Modern businesses rely heavily on printing technologies for branding, packaging, and product customization. In recent years, the UV DTF printer (Direct to Film) has emerged as a competitor to traditional printing solutions such as screen printing, sublimation, and heat transfer. Deciding whether a UV DTF printer is the right investment depends on your business needs, volume, and product type. This article provides an in-depth comparison to help you choose the right path forward.

Understanding UV DTF Printing

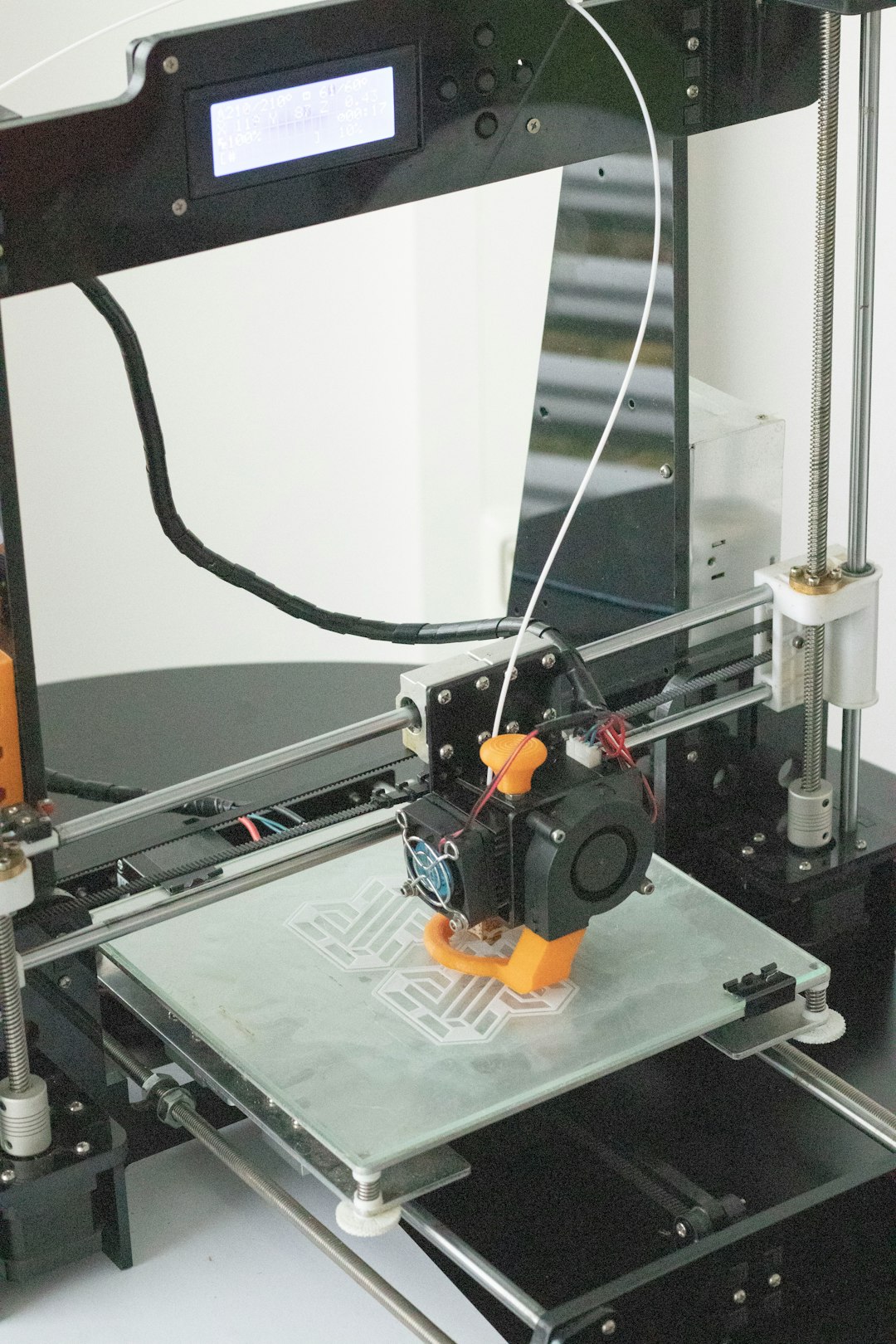

UV DTF printing is a relatively new method that uses ultraviolet light to cure or dry ink as it’s printed on a film. This film is then transferred onto various surfaces, including wood, glass, plastic, metal, and more. Unlike traditional methods, this process does not require pretreatment or weeding, making it highly efficient for custom and short-run applications.

Overview of Traditional Printing Methods

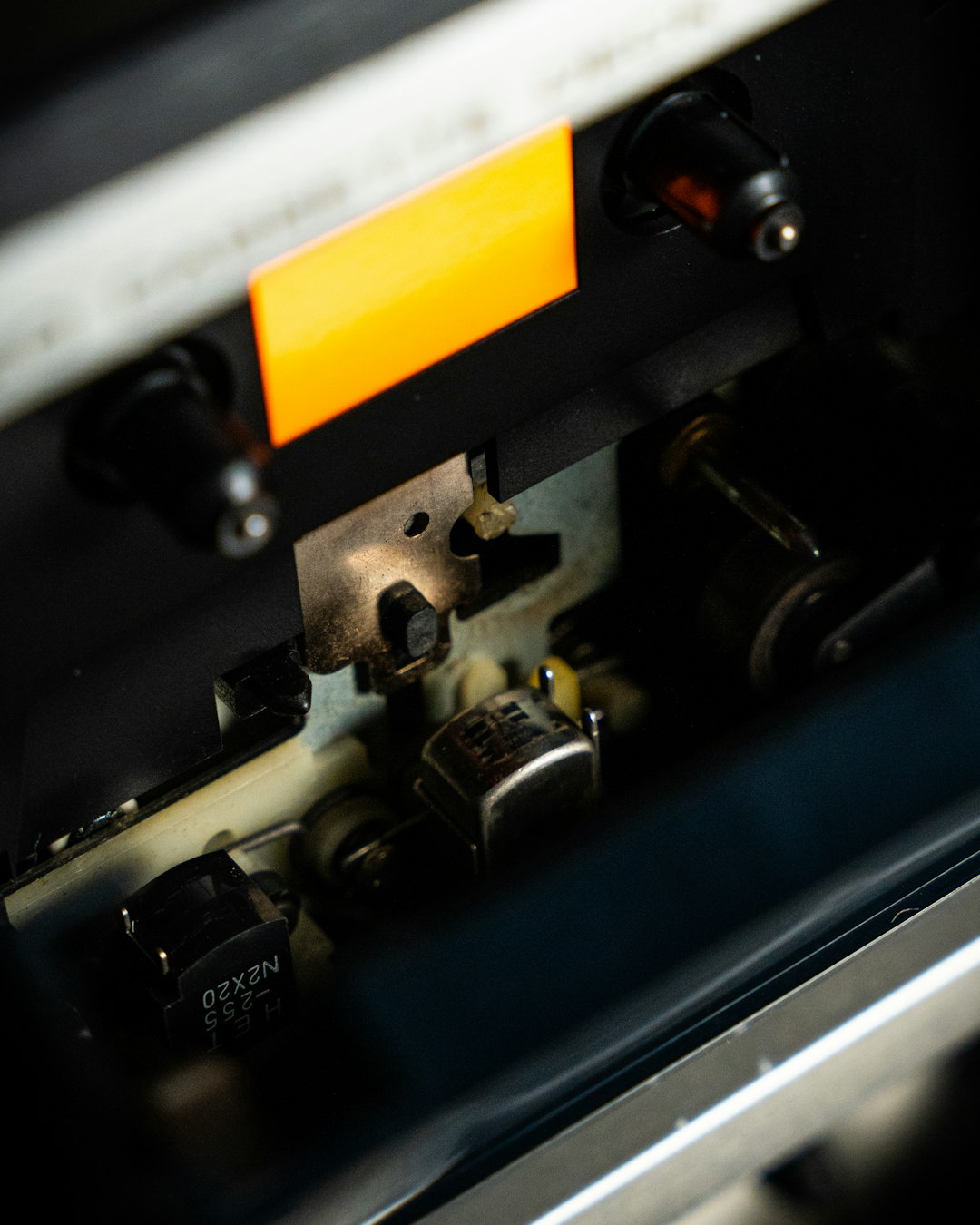

Traditional printing encompasses a range of techniques:

- Screen Printing – Best for bulk printing on flat surfaces like textiles and signage.

- Sublimation – Ideal for polyester-based materials and promotional products like mugs and t-shirts.

- Heat Transfer – Uses heat and pressure to transfer prints onto a variety of substrates.

These methods have been refined over decades and are widely used due to their reliability and cost-effectiveness in specific scenarios.

Comparison: UV DTF Printer vs. Traditional Printers

1. Flexibility and Application

UV DTF printers offer outstanding versatility by allowing applications on curved, irregular, and heat-sensitive objects without distortion or material damage. This feature opens up vast possibilities for customized and small-batch items.

In contrast, traditional printers often limit you to specific material types and shapes. Sublimation, for example, does not work on cotton-based materials, and screen printing cannot easily accommodate curved surfaces.

2. Setup Time and Workflow

The UV DTF method eliminates the need for pretreatment, cutting, and weeding. You simply print on the film and transfer directly. This reduced setup time is crucial for fulfilling short-run orders and maintaining production speed.

Traditional methods often require more preparation and manual labor, particularly when handling customized designs or limited quantities.

3. Print Quality and Durability

UV DTF technology delivers high-resolution prints with vibrant colors and excellent adhesion, even on hard or non-porous surfaces. The curing process ensures instant drying and long-lasting durability.

While traditional methods like screen printing also offer durable results, they may not achieve the same level of detail and color vibrancy, especially on unconventional materials.

4. Cost and Investment

Initial investment for a UV DTF printer can be higher than some traditional setups. However, the reduced labor, faster turnaround, and broad applicability may offer better ROI over time.

For high-volume, single-design production, traditional printing can still be more cost-efficient, especially since consumables and basic machinery are generally cheaper.

5. Learning Curve and Maintenance

UV DTF printers typically involve computer-aided design workflow and require understanding of RIP software. Once mastered, the process is straightforward and cleaner than handling screens, inks, and heat presses.

Traditional printing methods usually involve more manual processes, which can lead to inconsistent results without skilled labor. Maintenance also varies, with UV printers requiring regular print head cleaning and environmental controls to prevent nozzle clogs or UV lamp wear.

Which Is Better for Your Business?

The right choice ultimately depends on your business goals. Here are some scenarios to help guide your decision:

- You should choose UV DTF printing if you handle a wide range of custom jobs, work with irregular surfaces, or need a quick turnaround on short-run orders.

- You should stick with traditional printing if your focus is on bulk production of garments or a limited variety of print products with consistent designs.

In addition, businesses seeking to offer premium, high-detail personalization – such as boutique product makers or gift manufacturers – will find UV DTF printing an exceptional enhancement to their capabilities.

Conclusion

UV DTF technology represents a bold step forward for businesses looking to expand their printing services without the constraints of traditional processes. However, the decision should be balanced with cost, scalability, and product line considerations.

Evaluate your current workflow, customer demands, and long-term goals to determine whether UV DTF or a traditional method aligns best with your vision.